Good Better Best: Foundations

Intro

Welcome to Architecture Towards Neutral’s latest project – an innovative and informative blog series called Good Better Best.

Think of it as part material-and-product-review and part educational-series-for-homeowners. Each post will focus on one type of construction material or product. We’ll present you with the available options and categorize them as good, better, or best.

What is our criteria?

As an architecture firm focused on decarbonizing the built environment, we’ll be looking for the lowest possible reliance on fossil fuels, among other metrics.* That goes for the makeup of the product itself but also for the process required to create the product. We’ll also be looking at the lifecycle of the product or material to evaluate how well it can be broken down to its most basic parts at the end of its life and how well those parts can either biodegrade or be reused. All while keeping in mind the timestamp of carbon - meaning the more we can sequester and capture today is better. The near-term carbon balance is valued more heavily than the 60-year lifecycle used in many calculations.

Why the three categories?

We know that the best option for the planet isn’t always a feasible option for your building project. That may be because you don’t have access to the product due to budget constraints or because you can’t find the product in your area, or a host of other reasons that could make it difficult to acquire the “best” materials. By providing three categories, we’re acknowledging that it’s OK to be interested in (and excited about!) learning about the best possible materials while not yet being able to integrate them into your project.

One day in the not-so-far-off future, we envision a world where all new construction projects utilize bio-based products and materials from the “best” category and everyone living on this planet benefits from this new normal.

*Other considerations are Global Warming Potential (GWP) of materials, embodied carbon, loosely defined via Dynamic Life Cycle Analysis (DCLA), Carbon Dioxide Equivalent (CO2e) of materials, the use or presence of red-listed chemicals, and what data is shared via the Environmental Product Declaration (EPD) or via third party certifications such as Delcare (by International Living Building Futures, ILFI).

New Construction

Are you looking to build a new construction house with an insulated foundation? You should be; most energy codes in 2025 require exterior continuous insulation around a foundation wall. There are many different approaches to this type of construction, but one thing they all have in common is the intensive use of concrete. Concrete is typically poured into form work, which can either be reusable panels or custom built for each job with wood. Getting formwork correct is imperative to the dimensional accuracy of the concrete, and takes a significant amount of material itself. Enter ICFs.

Good

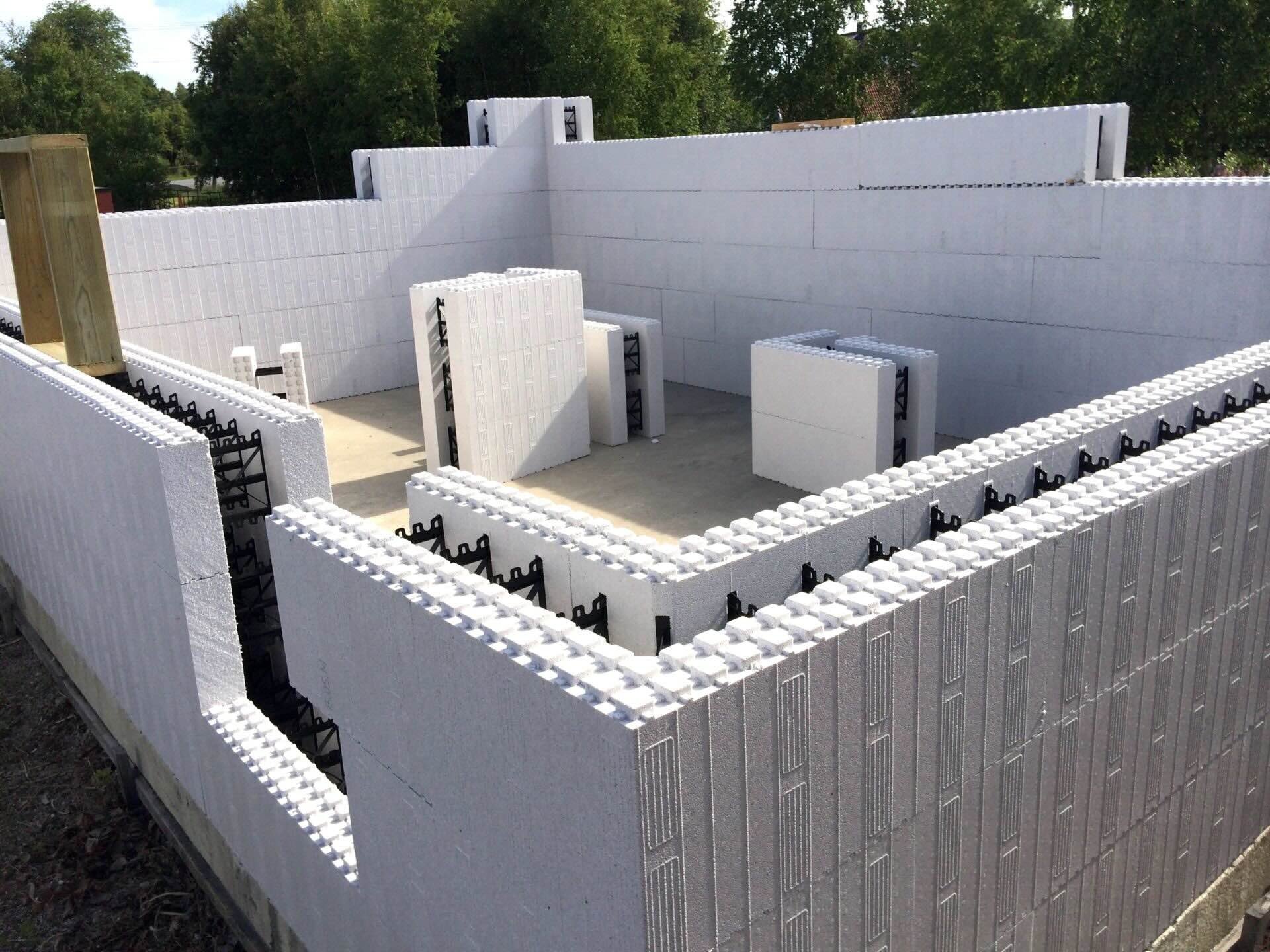

Look at all that foam! “High Performance" brought to you by the Big Oil Lobby.

Insulated Concrete Formworks (ICF) are modular blocks that act as the final insulation for the concrete foundation wall and also as the form work to pour the liquid concrete. The value of this, of course, is that no additional form work labor is required. Once the foundation is laid out with these blocks, they stay in place permanently. The downside is that these ICF blocks typically are made out of foam. In a high performance world this gets the job done, but in a multifaceted intersectional world that we live in it causes more harm to use a petroleum based insulation material.

Better

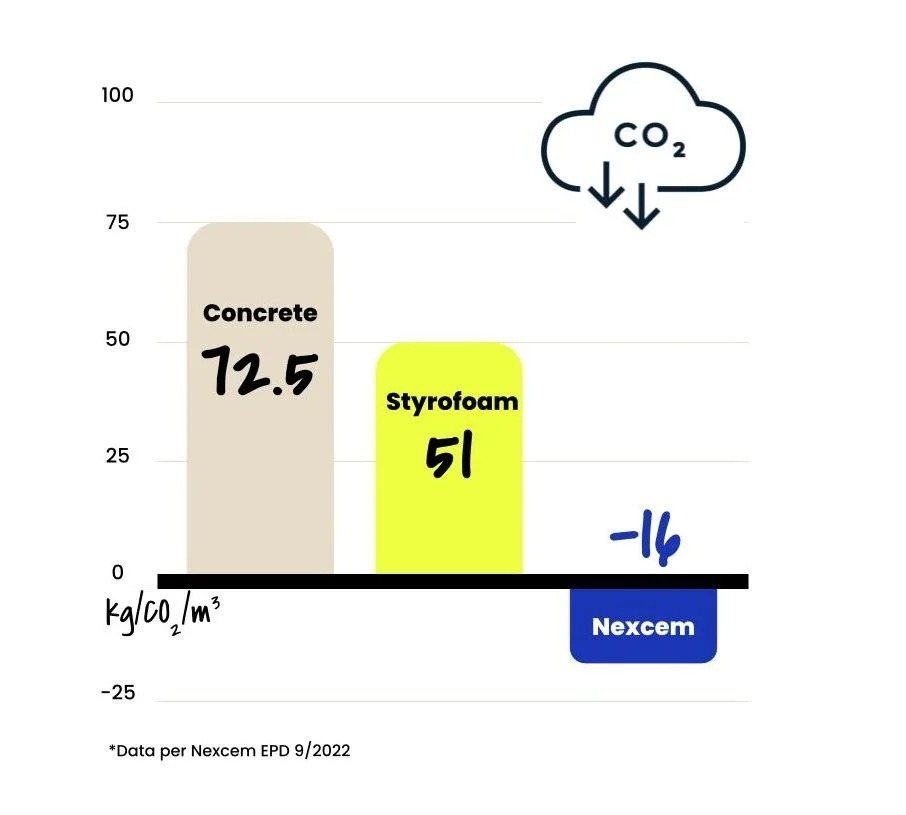

Enter Nexcem. This product utilizes wood pulp with minimal cement binding to create an insulated concrete form without foam. The blocks are lined with mineral fiber insulation on the interior of the cavity, protecting the insulation and shifting the thermal performance to the optimal location in the wall assembly. These forms are inherently structural themselves, allowing the use of less concrete in the overall project. The creation of these forms sequesters carbon through the growth of wood. Yet, this product does require some cement, which is a carbon intensive material. Overall, we see significant improvements with Nexcem over the more traditional foam ICFs.

Best

Castia by New Frameworks on helical piles.

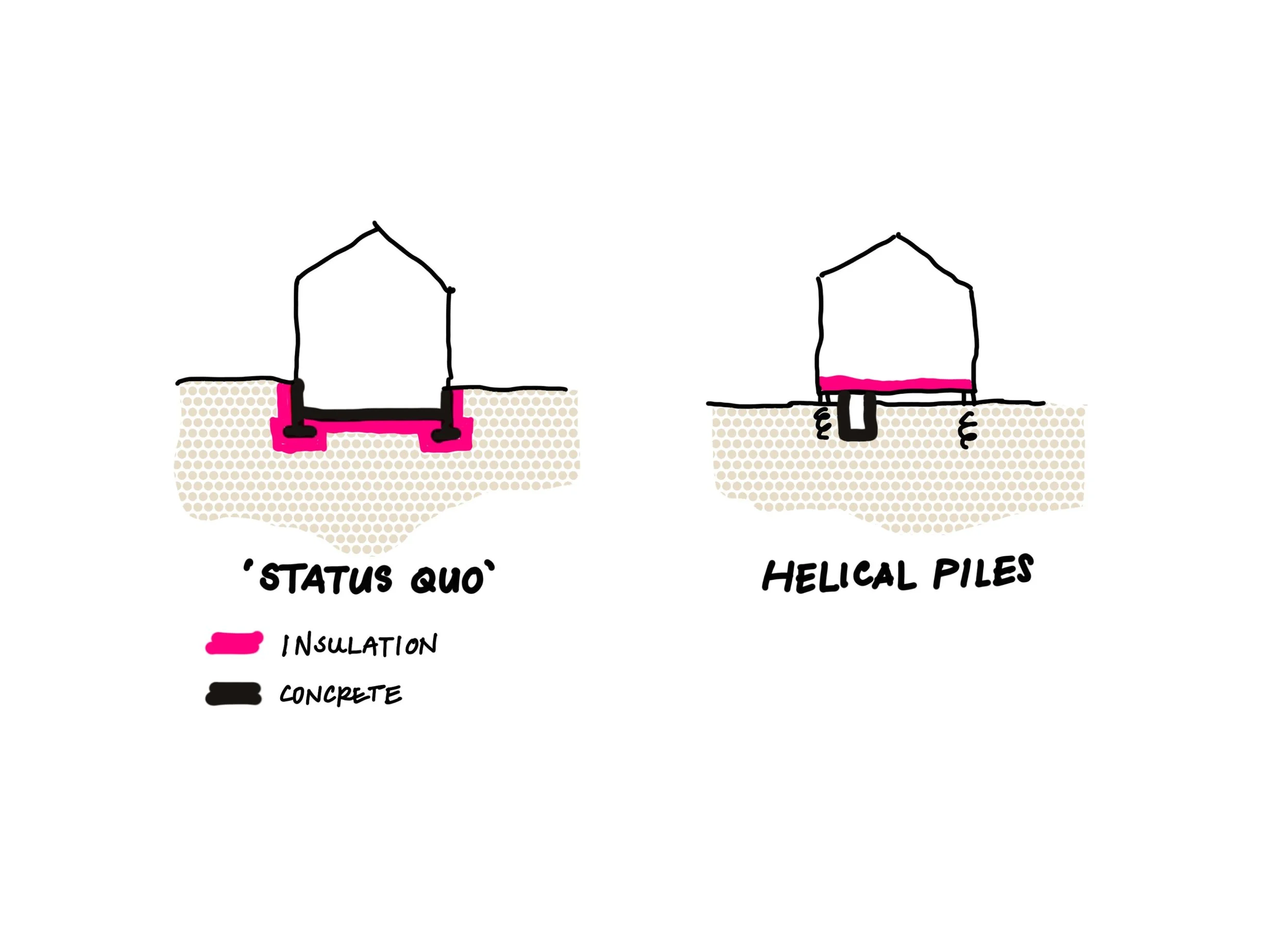

A traditional dug foundation is only one option. The best solution is to leave the Earth alone. New research shows that existing soil microbes have a very high opportunity to sequester carbon, the more of a site that is disturbed during a construction project, the worse the carbon impact of the project overall. Enter; helical piles.

Helical piles are as they sound, a spiral shaped pile that is drilled into the earth to a specified depth. The installation is done by a machine that locates the geometry with accuracy, drives up, screws down the pile and leaves the site. There is no downtime for liquid concrete delivery, curing, or disassembly of formwork. It eliminates the need for the highest embodied carbon material on a project, and is every bit as structurally functional as a default concrete foundation.

When using helical piles, it is crucial to carefully consider and prepare for in-ground utility connection. This approach shifts where the insulation is located. Now, instead of insulating the perimeter concrete, we insulate the floor. This means that we’re using the most planet-friendly approach by disturbing the soil as minimally as possible while still installing the required insulation in the most beneficial spot in the structure. See diagram.

Bonus best option?

The bonus best option is to improve an existing building. We will tackle that next…